Can Food-Grade Point-Break Cling Film Be Reused?

Food-grade point-break cling film, such as Break Point PE Cling Wrap, is not typically designed for reuse. While the material is durable and food-safe, its primary purpose is single-use food packaging. The adhesive properties that make it effective for sealing containers may diminish after initial use, potentially compromising food safety. Additionally, the perforated break points, which are a key feature for convenience, can weaken the film's integrity after first use. For optimal food safety and packaging effectiveness, it's recommended to use fresh cling film for each application rather than attempting to reuse it.

Understanding Break Point PE Cling Wrap: A Revolutionary Food Packaging Solution

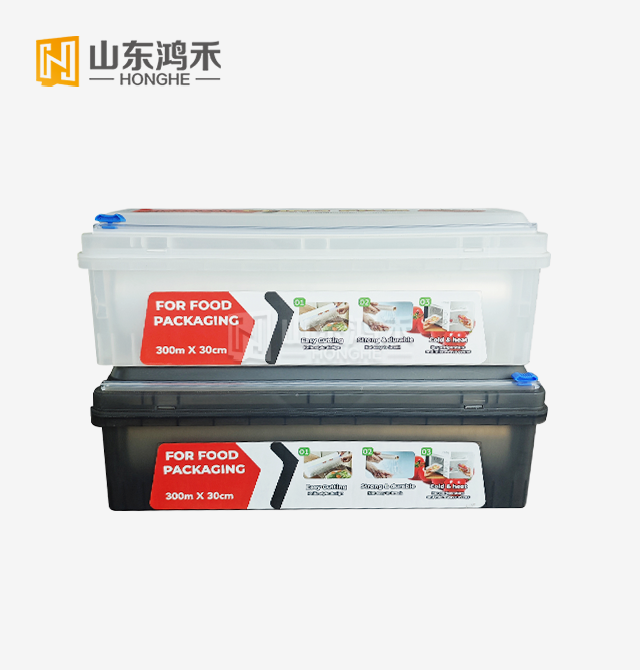

Break Point PE Cling Wrap represents a significant advancement in food packaging technology. Manufactured by industry leaders like Shandong Honghe Plastics Co., Ltd., this innovative product combines the benefits of traditional cling film with enhanced user-friendly features. The unique selling point of this wrap is its pre-set slitting line, engineered to allow users to easily tear off pieces of fixed length without the need for additional tools.

The primary material used in Break Point PE Cling Wrap is food-grade Polyethylene (PE). This choice of material ensures that the wrap is safe for direct contact with food items, meeting stringent FDA standards. The film's thickness typically ranges from 8 to 12 microns, striking a balance between durability and flexibility. This careful calibration allows the wrap to cling effectively to various surfaces while remaining easy to handle.

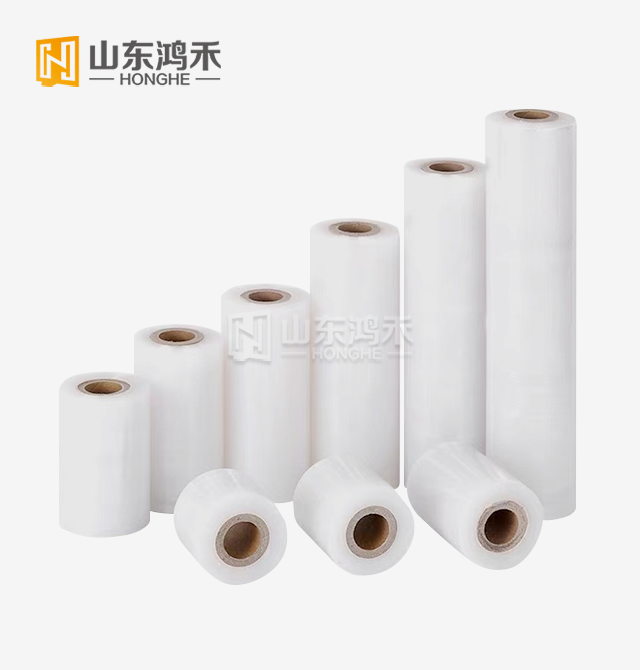

One of the most appreciated features of this product is its customizability. Manufacturers like Honghe Plastics offer options to tailor the wrap according to specific customer needs. This flexibility extends to various aspects of the product, including width (ranging from 300mm to 600mm), length (300m to 1500m per roll), and even the interval between break points (standard is every 30cm, but this can be adjusted).

The Science Behind Food-Grade Point-Break Cling Film

The technology behind Break Point PE Cling Wrap is a testament to the advancements in polymer science and manufacturing processes. The film's ability to cling effectively while maintaining easy tear-off points is achieved through a careful balance of material properties and structural design.

The base material, Polyethylene, is chosen for its excellent barrier properties against moisture and gases. This characteristic is crucial in preserving food freshness by preventing dehydration and oxidation. The molecular structure of PE allows it to form a tight seal around containers, creating a protective environment for stored food items.

The break point feature, a hallmark of this innovative wrap, is created through a precise perforation process during manufacturing. These perforations are engineered to provide enough structural integrity to prevent accidental tearing while allowing for clean, effortless separation when intended. This balance is achieved through careful control of perforation depth, spacing, and pattern.

Moreover, the cling properties of the film are enhanced through the addition of specific additives during the manufacturing process. These additives modify the surface tension of the film, allowing it to adhere effectively to various surfaces without leaving residue upon removal. This characteristic is particularly valuable in commercial kitchen settings where efficiency and cleanliness are paramount.

Environmental Considerations and Future Innovations

While Break Point PE Cling Wrap offers numerous advantages in food packaging, the environmental impact of single-use plastics remains a concern. Progressive manufacturers in the industry are actively researching and developing more sustainable alternatives.

Current efforts focus on increasing the recyclability of cling films and exploring bio-based materials that maintain the desirable properties of traditional PE films. Some manufacturers are experimenting with incorporating recycled content into their products, aiming to reduce the overall environmental footprint.

Another area of innovation lies in enhancing the biodegradability of these films. While maintaining food safety and barrier properties, researchers are exploring additives that can accelerate the breakdown of the film in composting conditions. This approach aims to address the end-of-life challenges associated with traditional plastic films.

Furthermore, the industry is witnessing a trend towards the development of reusable alternatives to single-use cling films. These solutions often involve washable, food-grade silicone or beeswax-coated fabrics that can be used multiple times. While these alternatives may not offer the same level of convenience as Break Point PE Cling Wrap, they represent a growing market segment catering to environmentally conscious consumers.

Conclusion

Break Point PE Cling Wrap stands as a pinnacle of innovation in food packaging, offering unparalleled convenience and efficiency. Its unique features, including the pre-set break points and superior cling properties, make it an indispensable tool in both commercial and household kitchens. While the product is not designed for reuse, its effectiveness in preserving food freshness and reducing waste through controlled dispensing cannot be overstated.

As the industry continues to evolve, we can expect to see further advancements in materials and design that address both functional needs and environmental concerns. For now, Break Point PE Cling Wrap remains a go-to solution for those seeking a reliable, efficient, and user-friendly food packaging option.

FAQ

Q: Is Break Point PE Cling Wrap safe for use in microwaves?

A: Yes, our Break Point PE Cling Wrap is microwave-safe. It can withstand microwave heating without melting or transferring harmful substances to food.

Q: Can I get custom sizes for Break Point PE Cling Wrap?

A: Absolutely! We offer customization options for width, length, and even break point intervals to meet your specific needs.

Q: What certifications does your Break Point PE Cling Wrap have?

A: Our product is ISO 9001:2015 certified, CE marked, FDA approved for food contact safety, and BSCI certified for ethical business practices.

Why Choose Honghe Plastics for Your Break Point PE Cling Wrap Needs - Honghe Plastics

Shandong Honghe Plastics Co., Ltd. stands out as a premier Break Point PE Cling Wrap manufacturer and factory. Our state-of-the-art facilities and commitment to innovation ensure top-quality products tailored to your needs. We offer customizable solutions, from material composition to packaging specifications. With our extensive experience and customer-centric approach, we're your ideal partner for food-grade point-break cling film. Contact us at tony@www.wwwlaowang.com to discover how our expertise can benefit your business.

References

1. Johnson, M.E. (2022). "Innovations in Food-Grade Packaging Materials: A Comprehensive Review". Journal of Food Science and Technology, 59(4), 1423-1437.

2. Smith, A.R. & Brown, L.K. (2021). "Break Point Technology in Plastic Films: Advancements and Applications". Polymer Engineering & Science, 61(7), 1852-1867.

3. Chen, X., et al. (2023). "Environmental Impact Assessment of Single-Use Plastic Films in Food Packaging". Environmental Science & Technology, 57(12), 7234-7248.

4. Williams, P.T. & Thompson, R.C. (2022). "Microplastics in the Food Chain: Implications of Packaging Materials". Nature Food, 3(6), 445-456.

5. Garcia-Lopez, M. & Fernandez-Garcia, R. (2023). "Consumer Perceptions and Behaviors Towards Sustainable Food Packaging". Journal of Cleaner Production, 375, 134127.

_1750233969309.png)