What Thickness Is Better For Machine-used Stretch Film?

As the name implies, machine-used stretch film is a film suitable for use on stretch film balers. There are many types of balers, mainly pallet stretch film balers, manual balers, fully automatic stretch film balers, pre-stretched stretch film balers, etc. Honghe Plastics will show you what thickness is better for machine-used stretch film?

There are three elements to judge the quality of the film: viscosity, elongation and puncture. Then the thickness is directly related to the elongation and puncture. So what thickness to choose is not only related to quality, but also affects the cost. For example, if a 2-wire film can be used, and you use 3.5-wire, then the cost will increase by 1.75 times.

Of course, not all items are better to be packaged thinner. It depends on whether it is a throwaway or heavy cargo, whether it is smooth and flat or with thorns. The heavier it is, the more angular and needle-like the surface is, then it is recommended to use a thicker film, at least the safety factor will be higher.

The thinner it is, the higher the proportion of metallocene in the composition structure will be. The thickness to be used is determined by the appearance of the goods, the requirements for stable load-bearing, economic benefits, user habits and the thickness production inertia of the manufacturer (in a word, the market determines the thickness).

Thickness recommendations:

Heavy goods with a smooth appearance---2.5-3 threads

Heavy goods with an uneven appearance---3 threads or more

Packaging pallet tossing goods---2 threads or more

Tossing goods (such as cardboard, etc.)---1.2 threads or more

The above suggestions are for reference only. Friends who need to communicate can contact us at?tony@www.wwwlaowang.com.

1757673908596.png)

站logo(1)_1750233969309.png)

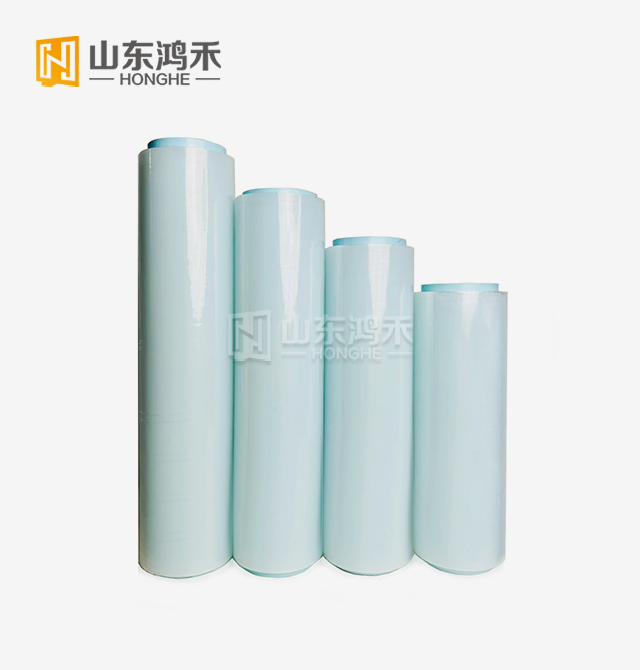

品管理-產(chǎn)品圖片/d0a4d1e08eb611f0b8d1cd28712d8f2a/Directory/PE Sealing Film_1757557628414.webp)