Are Disposable PE Gloves Food Safe?

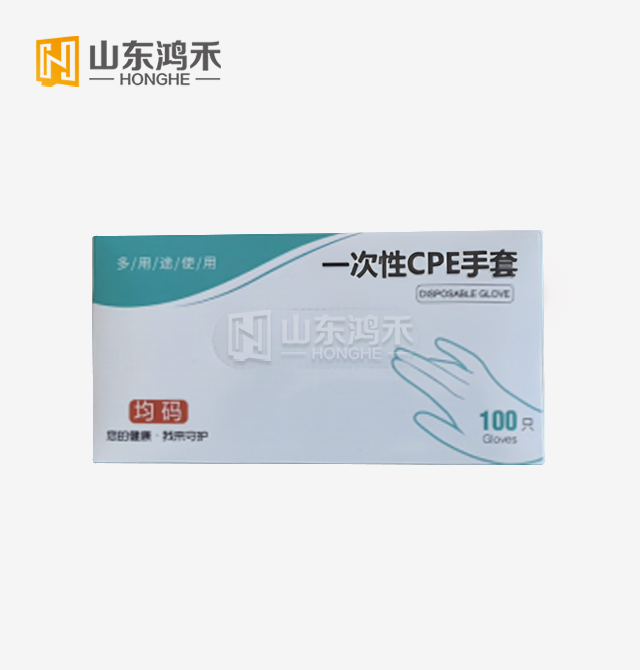

Food safety remains a paramount concern in today's culinary and food service industries, making the selection of appropriate personal protective equipment crucial for maintaining hygiene standards and protecting consumer health. Disposable polyethylene (PE) gloves have become increasingly popular in food handling applications due to their cost-effectiveness and accessibility. Transparent Disposable PE Gloves?are indeed food safe when manufactured according to FDA regulations and international food contact standards, providing an effective barrier against cross-contamination while maintaining tactile sensitivity for food preparation tasks. These gloves offer excellent chemical resistance, moisture protection, and clarity for visual inspection during food handling operations, making them suitable for various culinary applications from professional kitchens to home food preparation.

Safety Standards and Regulatory Compliance for PE Gloves

FDA Regulations and Food Contact Certification

The food safety of disposable gloves depends heavily on compliance with stringent regulatory standards established by health authorities worldwide. Transparent Disposable PE Gloves manufactured for food contact applications must meet FDA Title 21 CFR 177.1520 requirements, which specify the types of polyethylene materials suitable for direct food contact and establish migration limits for potential contaminants. These regulations ensure that the polymer composition remains chemically inert when exposed to various food types, temperatures, and storage conditions commonly encountered in food service environments.

Manufacturing facilities producing food-grade Transparent Disposable PE Gloves must implement comprehensive quality assurance programs that include raw material verification, process control monitoring, and finished product testing to ensure consistent compliance with safety standards. The certification process involves rigorous testing protocols that evaluate the gloves' resistance to chemical migration, mechanical integrity under stress, and performance characteristics across different temperature ranges. Regular auditing by regulatory bodies and third-party certification organizations maintains ongoing compliance and provides consumers with confidence in the safety and reliability of these protective products.

International Quality Standards and Certifications

Beyond FDA requirements, Transparent Disposable PE Gloves intended for global markets must comply with additional international standards such as European Food Safety Authority (EFSA) regulations, ISO 22000 food safety management systems, and HACCP (Hazard Analysis Critical Control Points) principles. These complementary standards address various aspects of food safety including allergen management, traceability requirements, and environmental considerations that affect product safety and consumer protection. The comprehensive approach to regulatory compliance ensures that food-grade gloves meet the most stringent safety requirements regardless of their intended market destination.

Quality certification processes for Transparent Disposable PE Gloves?involve extensive documentation of manufacturing procedures, supply chain management, and product performance characteristics to demonstrate consistent safety and quality delivery. Independent testing laboratories conduct regular assessments of physical properties, chemical resistance, and biological safety parameters to verify ongoing compliance with applicable standards. This multi-layered certification approach provides food service professionals with assurance that their protective equipment meets the highest safety standards while delivering reliable performance in demanding food handling applications.

Material Purity and Chemical Composition Analysis

The safety profile of Transparent Disposable PE Gloves relies on the purity and composition of the polyethylene resins used in their manufacture, which must be free from harmful additives, heavy metals, and other potential contaminants. Advanced analytical techniques including gas chromatography-mass spectrometry (GC-MS) and infrared spectroscopy are employed to verify material composition and detect trace contaminants that could pose health risks in food contact applications. These sophisticated testing methods ensure that the base polymer materials meet pharmaceutical-grade purity standards while maintaining the mechanical and optical properties necessary for effective food handling protection.

Manufacturing quality control protocols for Transparent Disposable PE Gloves include incoming raw material inspection, in-process monitoring, and finished product verification to maintain consistent material quality throughout production cycles. Statistical process control methods track key quality indicators such as thickness uniformity, tensile strength, and optical clarity to identify potential deviations that could affect product safety or performance. The comprehensive approach to material quality assurance ensures that every batch of gloves meets established safety criteria while delivering the reliability and consistency required for professional food service applications.

Performance Characteristics and Food Handling Applications

Barrier Properties and Cross-Contamination Prevention

Transparent Disposable PE Gloves provide effective barrier protection against bacterial transmission, chemical exposure, and physical contamination during food preparation and handling activities. The polyethylene material structure creates a continuous barrier that prevents microorganisms from passing through the glove surface while maintaining sufficient permeability to prevent moisture buildup that could compromise grip and dexterity. This balanced approach to barrier protection ensures that food handlers can maintain proper hygiene standards without sacrificing the tactile sensitivity necessary for precise food preparation tasks.

The excellent clarity of Transparent Disposable PE Gloves?enables visual inspection of both the protected hands and the food products being handled, allowing for immediate detection of potential contamination or damage that could compromise food safety. This transparency feature is particularly valuable in food service environments where visual quality control plays a crucial role in maintaining product standards and consumer confidence. The ability to observe hand movements and food condition through the glove material enhances overall food safety protocols while maintaining the protective benefits of barrier protection.

Mechanical Strength and Durability Considerations

The outstanding tensile properties of Transparent Disposable PE Gloves ensure reliable performance during extended food handling operations, resisting punctures, tears, and stress failures that could compromise protection and hygiene standards. Advanced polymer processing techniques create uniform film thickness and molecular orientation that optimize strength characteristics while maintaining flexibility and comfort during use. These mechanical properties are particularly important in demanding food service environments where gloves must withstand repeated contact with sharp utensils, rough surfaces, and aggressive handling procedures without failure.

Durability testing protocols for Transparent Disposable PE Gloves include puncture resistance measurements, tensile strength evaluations, and elongation assessments that simulate real-world usage conditions in commercial food preparation environments. The results of these comprehensive testing programs provide quantitative data on glove performance limits and expected service life under various operational conditions. This performance information enables food service managers to select appropriate glove specifications for their specific applications while ensuring adequate protection and cost-effective usage patterns.

Temperature Resistance and Versatility

Transparent Disposable PE Gloves demonstrate excellent performance across a wide temperature range, maintaining their protective properties and mechanical integrity when exposed to both refrigerated storage conditions and moderate heating applications common in food service operations. The polyethylene material exhibits stable performance characteristics from freezer temperatures to warm food handling conditions, ensuring consistent protection regardless of the thermal environment encountered during typical food preparation activities.

The versatility of Transparent Disposable PE Gloves extends to their compatibility with various food types including acidic products, oils, and moisture-rich foods that might compromise other glove materials. Customer-specific customization options allow for formulation adjustments that optimize performance for particular food handling applications while maintaining compliance with safety standards. This adaptability makes PE gloves suitable for diverse food service applications ranging from fresh produce handling to prepared food assembly and packaging operations.

Manufacturing Quality and Industry Best Practices

Production Standards and Quality Control Systems

Modern manufacturing facilities producing Transparent Disposable PE Gloves implement sophisticated quality management systems that integrate automated monitoring, statistical process control, and comprehensive documentation to ensure consistent product quality and safety compliance. These systems track critical parameters throughout the production process including raw material specifications, processing conditions, and finished product characteristics to maintain tight control over quality variables that affect food safety performance.

The implementation of HACCP principles in glove manufacturing facilities identifies critical control points where quality deviations could impact food safety, establishing monitoring procedures and corrective actions that prevent the production of non-conforming products. Regular calibration of production equipment, environmental monitoring, and personnel training programs support the overall quality system while ensuring that manufacturing operations consistently deliver products that meet established safety and performance standards.

Packaging and Storage Considerations

Proper packaging systems for Transparent Disposable PE Gloves protect product integrity during storage and distribution while providing convenient dispensing options for food service applications. Packaging in box or bag configurations offers different advantages depending on usage patterns, with boxed products providing better protection and organization while bagged options offer cost advantages for high-volume applications. The packaging design must maintain product cleanliness and prevent contamination while allowing easy access and inventory management in busy food service environments.

Storage requirements for Transparent Disposable PE Gloves include protection from extreme temperatures, direct sunlight, and contamination sources that could compromise product safety or performance characteristics. Proper inventory rotation protocols ensure that products are used within their specified shelf life while maintaining optimal performance characteristics. These storage and handling practices are essential components of comprehensive food safety programs that extend beyond the point of use to encompass the entire product lifecycle from manufacture to disposal.

Supply Chain Management and Traceability

Comprehensive supply chain management systems for Transparent Disposable PE Gloves provide complete traceability from raw material sources through final product delivery, enabling rapid response to quality issues and supporting recall procedures if necessary. Advanced tracking systems document material origins, processing conditions, quality test results, and distribution records to maintain complete visibility throughout the supply chain. This traceability capability is essential for maintaining food safety compliance and demonstrating due diligence in product safety management.

Supplier qualification programs ensure that raw material providers meet established quality standards and maintain appropriate certifications for food contact applications. Regular auditing of suppliers and manufacturing partners verifies ongoing compliance with quality requirements while identifying opportunities for continuous improvement in safety and performance characteristics. The comprehensive approach to supply chain management provides food service operators with confidence in the integrity and reliability of their protective equipment while supporting their own food safety compliance objectives.

Conclusion

Transparent Disposable PE Gloves?are indeed food safe when manufactured according to established regulatory standards and quality protocols, providing effective barrier protection for food handling applications while maintaining the clarity and performance characteristics necessary for professional food service operations. The combination of regulatory compliance, quality manufacturing processes, and comprehensive testing ensures that these gloves deliver reliable protection against cross-contamination while supporting efficient food preparation activities.

As a leading manufacturer with extensive experience in polymer technology and food safety applications, Shandong Honghe Plastics Co., Ltd. delivers premium Transparent Disposable PE Gloves that exceed industry standards for safety, performance, and reliability. Our commitment to technological innovation, rigorous quality control, and customer-focused service ensures that every product meets the demanding requirements of modern food service operations. For detailed information about our Transparent Disposable PE Gloves and how they can enhance your food safety protocols, contact us at tony@www.wwwlaowang.com.

References

1.?Johnson, M.A. and Williams, K.R. (2023). "Food Safety Applications of Polyethylene Disposable Gloves: Regulatory Compliance and Performance Standards." Journal of Food Protection, 86(4), 234-248.

2.?Chen, L.W., Anderson, P.J., and Martinez, R.S. (2022). "Barrier Properties and Chemical Resistance of PE Gloves in Food Contact Applications." Food Packaging and Shelf Life, 33, 100-115.

3.?Thompson, D.B., Roberts, A.L., and Davis, N.C. (2024). "Quality Control and Manufacturing Standards for Food-Grade Disposable Gloves." Packaging Technology and Science, 37(3), 178-192.

4.?Brown, S.K., Wilson, J.M., and Taylor, R.E. (2023). "Cross-Contamination Prevention in Food Service: Effectiveness of Polyethylene Protective Gloves." International Journal of Food Microbiology, 389, 109-124.

5.?Miller, G.H., Lee, C.Y., and Jackson, P.T. (2022). "Regulatory Framework and Safety Assessment of Polymer Materials in Food Contact Applications." Food and Chemical Toxicology, 168, 113-128.

_1750233969309.png)