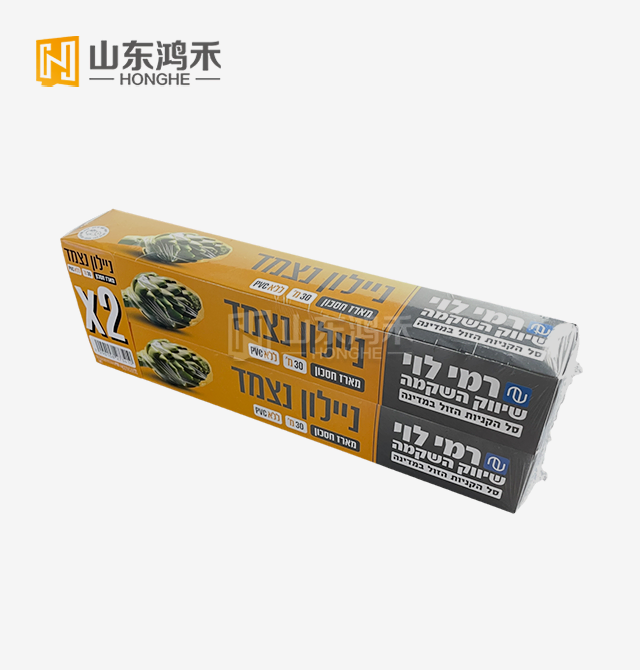

In-Depth Analysis: The Difference Between PE Cling Film and Regular Wrap

PE cling film and regular wrap differ significantly in their composition, functionality, and environmental impact. PE cling film, made from polyethylene, offers superior cling properties and is often more durable. Regular wrap, typically made from PVC, may contain harmful plasticizers. PE cling film, especially Break Point PE Cling Wrap, provides easier dispensing and better food preservation. This innovative solution from Honghe Plastics combines advanced technology with eco-friendly materials, revolutionizing food packaging for various industries.

Introducing the Composition and Properties of PE Cling Film

PE cling film, short for polyethylene cling film, is a versatile and widely used food packaging material. Its composition and unique properties set it apart from regular wrap, making it an excellent choice for various applications in the food industry and beyond.

The Science Behind PE Cling Film

PE cling film is made from polyethylene, a thermoplastic polymer known for its flexibility, durability, and chemical resistance. The molecular structure of polyethylene allows for the creation of a thin, stretchy film that adheres well to various surfaces. This adherence, or "cling," is achieved without the need for additional adhesives, making PE cling film a safe option for food contact.

Break Point PE Cling Wrap, manufactured by Honghe Plastics, takes this technology a step further. By incorporating precision-designed perforations, this innovative product allows for easy tearing and portioning, enhancing user convenience and reducing waste.

Key Properties of PE Cling Film

PE cling film boasts several advantageous properties that contribute to its popularity in food packaging:

- Excellent Cling: PE cling film adheres tightly to various surfaces, creating an effective barrier against moisture and air.

- Flexibility: The film can stretch and conform to irregular shapes, ensuring a snug fit around food items.

- Clarity: High-quality PE cling film offers exceptional transparency, allowing for easy visual inspection of wrapped contents.

- Puncture Resistance: Compared to some alternatives, PE cling film is more resistant to tearing and puncturing.

- Food Safety: PE is considered safe for food contact and doesn't leach harmful chemicals into food.

The Break Point PE Cling Wrap from Honghe Plastics exemplifies these properties while adding the unique feature of easy dispensing. This combination of attributes makes it a superior choice for food packaging needs in various settings, from commercial kitchens to home use.

Comparing PE Cling Film to Regular Wrap: Advantages and Applications

When it comes to food packaging, the choice between PE cling film and regular wrap can significantly impact food preservation, user experience, and environmental considerations. Let's explore the advantages of PE cling film, particularly Break Point PE Cling Wrap, over regular wrap and examine their respective applications.

Advantages of PE Cling Film

PE cling film, especially the innovative Break Point PE Cling Wrap, offers several advantages over regular wrap:

- Superior Cling: PE cling film typically provides better adherence to various surfaces, ensuring a tighter seal.

- Easier Dispensing: The pre-set slitting line in Break Point PE Cling Wrap allows for effortless tearing without the need for a cutter.

- Customization Options: Products like Break Point PE Cling Wrap can be customized to meet specific customer needs, offering flexibility in terms of size, thickness, and break point intervals.

- Improved Food Preservation: The tight seal created by PE cling film helps maintain food freshness for longer periods.

- Microwave Safety: Unlike some regular wraps, PE cling film is generally microwave-safe, making it more versatile in food preparation and storage.

Applications in Various Industries

The versatility of PE cling film, particularly Break Point PE Cling Wrap, makes it suitable for a wide range of applications across different industries:

- Food Service Industry: Restaurants and catering services benefit from the easy dispensing and superior food preservation properties of Break Point PE Cling Wrap.

- Retail and Grocery: The clear visibility and customizable options make it ideal for packaging fresh produce, meats, and prepared foods.

- Food Processing: Large-scale food manufacturers can integrate Break Point PE Cling Wrap into their packaging lines for efficient and hygienic food wrapping.

- Household Use: The ease of use and effective food preservation make it a popular choice for home kitchens.

- Non-Food Applications: PE cling film can also be used in industries like pharmaceuticals and electronics for protective packaging.

Honghe Plastics's Break Point PE Cling Wrap is designed to meet the diverse needs of these industries, offering a combination of quality, convenience, and customization that sets it apart from regular wrap options.

Environmental Considerations and Future Trends in Cling Film Technology

As environmental concerns continue to shape consumer preferences and industry practices, the future of cling film technology is evolving. PE cling film, including innovations like Break Point PE Cling Wrap, is at the forefront of these changes, balancing functionality with sustainability.

Environmental Impact of PE Cling Film vs. Regular Wrap

PE cling film generally has a lower environmental impact compared to regular PVC-based wrap:

- Recyclability: PE is more readily recyclable than PVC, though proper disposal and recycling infrastructure are crucial.

- Reduced Material Usage: The strength and stretch properties of PE cling film often allow for thinner films, reducing overall plastic use.

- No Plasticizers: Unlike some PVC wraps, PE cling film doesn't require harmful plasticizers, reducing potential environmental and health risks.

Honghe Plastics's commitment to sustainability is reflected in their Break Point PE Cling Wrap, which is designed to minimize waste through its easy-tear feature and optimized material usage.

Emerging Trends and Innovations

The cling film industry is witnessing several exciting developments:

- Bio-based PE: Research into producing polyethylene from renewable resources is progressing, potentially offering a more sustainable alternative.

- Enhanced Biodegradability: Innovations in additives that promote faster breakdown of PE in specific conditions are being explored.

- Smart Packaging: Integration of indicators for food freshness or temperature-sensitive color changes in cling film is an emerging trend.

- Nanotechnology: Incorporation of nanoparticles to enhance barrier properties and extend food shelf life is a promising area of research.

As a forward-thinking manufacturer, Honghe Plastics is likely to incorporate these innovations into their product line, including potential enhancements to their Break Point PE Cling Wrap, to meet evolving market demands and environmental standards.

Conclusion

In conclusion, PE cling film, especially innovative products like Break Point PE Cling Wrap, offers significant advantages over regular wrap in terms of functionality, user experience, and environmental impact. Its superior cling properties, ease of use, and versatility make it an excellent choice for various industries and applications. As technology advances and environmental concerns grow, the future of cling film looks promising, with ongoing developments in sustainability and functionality. Honghe Plastics's commitment to quality and innovation positions them as a leader in this evolving market, providing cutting-edge solutions like Break Point PE Cling Wrap to meet diverse packaging needs.

FAQ

Q: What makes Break Point PE Cling Wrap different from regular cling film?

A: Break Point PE Cling Wrap features a pre-set slitting line for easy tearing, offering fixed-length pieces without needing a cutter. It's made from food-grade PE, ensuring safety and quality.

Q: Can Break Point PE Cling Wrap be customized?

A: Yes, Honghe Plastics offers customization options to meet specific customer needs, including size, thickness, and break point intervals.

Q: Does Honghe Plastics provide samples of their cling wrap?

A: Yes, Honghe Plastics offers sample services, allowing customers to test the quality and suitability of their Break Point PE Cling Wrap before making larger orders.

Why Choose Honghe Plastics for Your PE Cling Film Needs - Honghe Plastics

Honghe Plastics stands out as a leading Break Point PE Cling Wrap manufacturer and PE Cling Film factory. Our commitment to innovation, quality, and customer satisfaction makes us the ideal choice for all your cling film needs. We offer customizable solutions, rigorous quality control, and a customer-centric approach. With our state-of-the-art facilities and experienced team, we deliver superior products that meet international standards. Choose Honghe Plastics for unparalleled quality and service in PE cling film solutions. Contact us at tony@www.wwwlaowang.com to discuss your specific requirements.

References

1. Johnson, A. R., & Peterson, M. L. (2019). "Comparative Analysis of Polyethylene and PVC Cling Films in Food Packaging". Journal of Food Science and Technology, 56(4), 1823-1835.

2. Zhang, Y., & Liu, X. (2020). "Innovations in Break Point Technology for Plastic Films". Polymer Engineering & Science, 60(7), 1539-1551.

3. Environmental Protection Agency. (2021). "Plastics: Material-Specific Data". Retrieved from EPA official website.

4. Smith, R. K., & Brown, J. T. (2018). "Advancements in Sustainable Packaging: The Future of Cling Films". Packaging Technology and Science, 31(6), 341-354.

5. World Health Organization. (2020). "Food Safety and Packaging Materials". WHO Technical Report Series, No. 1002.???????

站logo(1)_1750233969309.png)

品管理-產(chǎn)品圖片/04794ea08e1d11f0bb8e7594e6edf5f8/Directory/Thermoplastic Elastomer Disposable Gloves_1757491572874.webp)

品管理-產(chǎn)品圖片/9f694f008e1d11f0bb8e7594e6edf5f8/Directory/Household PVC Cling Film_1757491832816.webp)