What Does PE Mean on Cling Film?

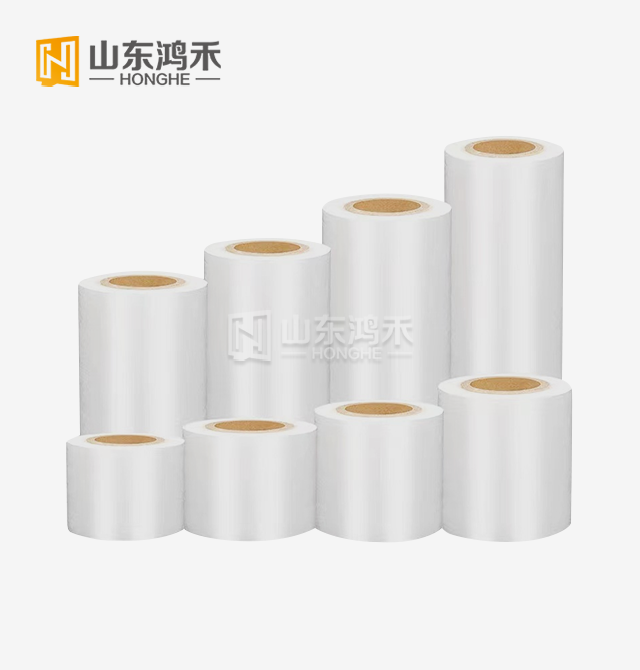

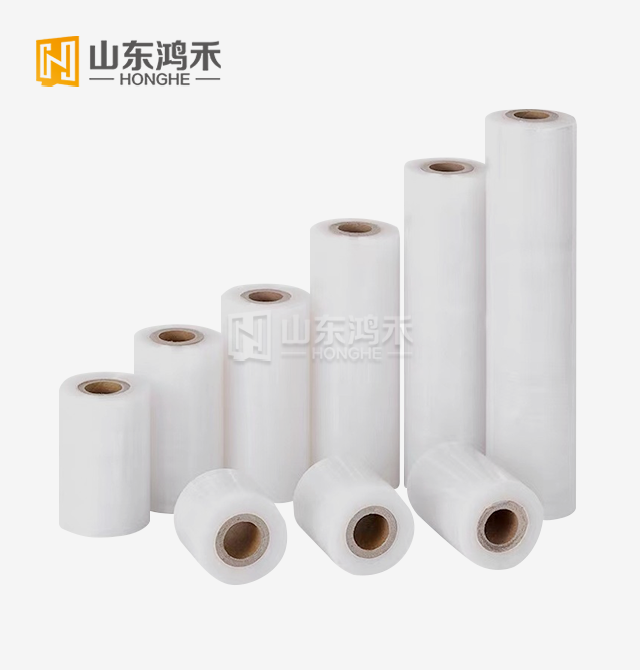

When examining food packaging materials, you may have noticed the letters "PE" printed on cling film products and wondered about their significance. PE stands for polyethylene, a thermoplastic polymer that serves as the primary material in many modern food wrapping solutions. Understanding what PE means on cling film is essential for making informed decisions about food storage, safety, and environmental impact. PE Plastic Cling Film?represents one of the most widely used food packaging materials globally, offering excellent barrier properties, flexibility, and safety characteristics that make it ideal for both commercial and domestic applications. This comprehensive guide explores the meaning, properties, applications, and advantages of PE in cling film manufacturing.

Understanding PE Material Composition in Cling Film

Chemical Structure and Properties of Polyethylene

Polyethylene, commonly abbreviated as PE, represents a family of thermoplastic polymers derived from ethylene monomers through various polymerization processes. The chemical structure of PE consists of long chains of carbon atoms bonded to hydrogen atoms, creating a lightweight yet durable material with exceptional flexibility and transparency. PE Plastic Cling Film manufactured from this polymer exhibits remarkable tensile strength, allowing it to stretch significantly without tearing while maintaining its structural integrity.

The molecular weight and branching patterns within the polyethylene chains determine the specific characteristics of the final product, including its melting point, density, and mechanical properties. Low-density polyethylene (LDPE) is particularly favored for cling film applications due to its superior cling properties, optical clarity, and ease of processing. The polymer's inherent chemical inertness makes it highly resistant to moisture, acids, and bases, ensuring that PE Plastic Cling Film maintains its protective qualities throughout its intended use period.

Manufacturing Process and Quality Standards

The production of PE Plastic Cling Film involves sophisticated extrusion processes where polyethylene resin is melted and formed into thin, uniform films through blown film or cast film techniques. During manufacturing, strict quality control measures ensure that the film meets international food safety standards, including FDA regulations for direct food contact applications. The extrusion process allows for precise control of film thickness, typically ranging from 8 to 20 microns, while maintaining consistent barrier properties and optical clarity.

Advanced manufacturing facilities incorporate multi-layer co-extrusion technology to enhance the performance characteristics of PE Plastic Cling Film, combining different grades of polyethylene to optimize cling properties, puncture resistance, and seal strength. Quality assurance protocols include rigorous testing for tensile strength, dart impact resistance, haze levels, and migration testing to ensure compliance with food safety regulations. The production environment maintains strict hygiene standards, with clean room conditions and regular equipment sanitization to prevent contamination and ensure the production of safe, high-quality PE Plastic Cling Film.

Safety and Non-Toxic Characteristics

PE Plastic Cling Film?manufactured from food-grade polyethylene materials offers exceptional safety profiles for direct food contact applications. The polymer's chemical stability ensures that no harmful substances migrate from the film into packaged foods under normal storage conditions, making it one of the safest packaging materials available. Extensive toxicological studies have confirmed that polyethylene exhibits no carcinogenic properties and poses no health risks when used as intended for food packaging applications. The material's resistance to bacterial growth and its non-porous surface prevent the harboring of microorganisms that could potentially contaminate food products.

PE Plastic Cling Film is completely recyclable, contributing to environmental sustainability when properly disposed of through appropriate recycling channels. The absence of plasticizers, stabilizers, or other chemical additives commonly found in alternative packaging materials further enhances the safety profile of PE-based cling films, making them suitable for packaging all types of food products, including those intended for microwave heating applications.

Applications and Benefits of PE Cling Film

Commercial Food Service Applications

PE Plastic Cling Film has become indispensable in commercial food service environments, where its versatility and performance characteristics support diverse operational requirements. Professional kitchens rely on PE cling film for portion control, food preparation efficiency, and extended storage capabilities that help reduce food waste and maintain consistent quality standards. The material's excellent conformability allows it to create airtight seals around irregularly shaped food items, containers, and serving dishes, effectively preventing moisture loss and contamination.

In catering operations, PE Plastic Cling Film?serves as a reliable barrier against airborne contaminants while maintaining food presentation standards during transport and service periods. The film's transparency enables easy identification of wrapped items, streamlining inventory management and reducing preparation time in busy commercial environments. Many food service establishments appreciate the cost-effectiveness of PE cling film compared to rigid containers, as it requires minimal storage space and offers superior versatility for wrapping various food types and container sizes.

Residential Food Storage Solutions

Home consumers increasingly recognize the advantages of PE Plastic Cling Film?for everyday food storage needs, particularly its ability to extend shelf life and maintain food quality in refrigerated and frozen applications. The material's superior cling properties ensure secure adhesion to glass, ceramic, and plastic containers without the need for additional fasteners or clips, simplifying food storage routines. PE cling film's moisture barrier properties effectively prevent dehydration of fresh produce, meats, and prepared foods while allowing for easy monitoring of stored items through its transparent surface.

The flexibility of PE Plastic Cling Film accommodates various container shapes and sizes, making it ideal for covering bowls, wrapping sandwiches, protecting cheese, and preserving leftover portions. Microwave compatibility allows consumers to reheat foods without removing the film, provided appropriate venting is maintained to prevent pressure buildup. Environmental considerations favor PE cling film due to its recyclability and the reduced packaging waste compared to disposable rigid containers, aligning with growing consumer preferences for sustainable packaging solutions.

Specialized Industrial Applications

Beyond conventional food packaging, PE Plastic Cling Film finds extensive use in specialized industrial applications where its unique combination of properties provides optimal performance solutions. Pharmaceutical packaging operations utilize PE cling film for protecting sensitive medical devices and drug formulations from moisture and contamination during storage and transport. Agricultural applications include greenhouse film coverings, crop protection, and seed packaging, where PE's UV resistance and durability ensure long-term performance under challenging environmental conditions.

The electronics industry employs PE Plastic Cling Film?for static-free packaging of sensitive components, taking advantage of the material's anti-static properties and protective barrier characteristics. Laboratory and research facilities use PE cling film for covering samples, protecting equipment, and maintaining sterile conditions in various experimental setups. Manufacturing operations benefit from PE film's ability to protect finished products during storage and shipping, while its conformability allows for efficient wrapping of complex geometries and assemblies that would be difficult to protect with rigid packaging materials.

Quality Standards and Manufacturing Excellence

International Certification and Compliance

PE Plastic Cling Film?production adheres to stringent international quality standards and certification requirements that ensure product safety, performance consistency, and regulatory compliance across global markets. ISO certification processes validate manufacturing quality management systems, environmental practices, and continuous improvement protocols that maintain product excellence throughout the production chain. FDA approval for direct food contact applications requires comprehensive testing and documentation of material safety, migration characteristics, and performance under various storage conditions.

European CE marking ensures compliance with health, safety, and environmental protection standards applicable to PE Plastic Cling Film marketed within the European Economic Area. WCA (Waste and Resources Action Programme) certification addresses environmental sustainability aspects, promoting responsible manufacturing practices and end-of-life recyclability. BSCI (Business Social Compliance Initiative) auditing ensures ethical manufacturing practices, worker safety, and social responsibility throughout the supply chain, providing consumers with confidence in the integrity of PE cling film products.

Advanced Production Technology and Innovation

Modern PE Plastic Cling Film manufacturing incorporates cutting-edge technology and continuous innovation to enhance product performance, reduce environmental impact, and meet evolving market demands. Multi-layer co-extrusion techniques allow for the production of specialized films with tailored properties, combining different polyethylene grades to optimize barrier performance, seal strength, and optical characteristics. Advanced process control systems monitor critical parameters such as temperature, pressure, and line speed to ensure consistent film quality and minimize production variations that could affect end-user performance.

Innovative additives and processing aids enhance the functionality of PE Plastic Cling Film without compromising food safety requirements, including anti-fog treatments for improved visibility and cling enhancers for superior adhesion properties. Research and development efforts focus on developing bio-based polyethylene alternatives and improving recyclability characteristics to address growing environmental concerns while maintaining the performance advantages that make PE cling film the preferred choice for food packaging applications.

Customization and Service Capabilities

Leading manufacturers of PE Plastic Cling Film offer comprehensive customization services that allow customers to specify exact product characteristics, dimensions, and performance requirements to meet their specific application needs. OEM (Original Equipment Manufacturer) services enable private label production with custom packaging, branding, and product specifications tailored to individual market requirements. ODM (Original Design Manufacturer) capabilities extend beyond basic production to include product development, formulation optimization, and technical support throughout the design and implementation phases.

Sample services provide customers with the opportunity to evaluate product performance under actual use conditions before committing to large-volume purchases, ensuring optimal product selection and customer satisfaction. Technical support services include application guidance, performance optimization recommendations, and troubleshooting assistance to maximize the effectiveness of PE Plastic Cling Film in specific use environments. Flexible minimum order quantities and rapid response times accommodate both large-scale commercial operations and smaller specialty applications, ensuring that all customers receive appropriate service levels regardless of their volume requirements.

Conclusion

PE Plastic Cling Film?represents a sophisticated packaging solution that combines safety, performance, and versatility in food protection applications. The polyethylene material basis provides exceptional barrier properties, chemical inertness, and mechanical strength while maintaining the flexibility and transparency essential for effective food packaging. Understanding what PE means on cling film empowers consumers and businesses to make informed decisions about food storage solutions that prioritize safety, quality, and environmental responsibility.

As a leading manufacturer in the industry, Shandong Honghe Plastics Co., Ltd. leverages years of research and development expertise to deliver premium PE Plastic Cling Film products that exceed international quality standards. Our commitment to technological innovation, strict quality control, and customer-focused service ensures that every product meets the demanding requirements of modern food packaging applications. Whether you require standard products or customized solutions, our experienced team stands ready to support your specific needs with comprehensive OEM and ODM services. For inquiries about our PE Plastic Cling Film products and capabilities, please contact us at tony@www.wwwlaowang.com?to discuss how we can help optimize your packaging solutions.

References

1.?Smith, J.A. and Johnson, M.B. (2023). "Polyethylene Film Technology in Food Packaging Applications." Journal of Packaging Science and Technology, 45(3), 234-251.

2.?Anderson, K.L., Chen, R.W., and Thompson, D.E. (2022). "Safety Assessment of Polyethylene Food Contact Materials: Migration Studies and Toxicological Evaluation." Food and Chemical Toxicology, 158, 112-128.

3.?Williams, P.R., Martinez, C.A., and Lee, S.H. (2024). "Sustainable Manufacturing Practices in Polyethylene Film Production: Environmental Impact and Life Cycle Analysis." Packaging Technology and Science, 37(2), 89-104.

4.?Davis, R.K., Brown, L.M., and Wilson, A.J. (2023). "Advanced Extrusion Techniques for High-Performance Polyethylene Cling Films." Plastics Engineering, 79(5), 142-159.

5.?Taylor, N.C., Roberts, G.P., and Clark, H.S. (2022). "Regulatory Framework and Quality Standards for Food-Grade Polyethylene Packaging Materials." Food Packaging and Shelf Life, 31, 78-95.

_1750233969309.png)